We use cookies to make your experience of our website better. Some of the cookies we use are essential for parts of the site to operate and have already been set. Find out more about the cookies we use and how to block or delete cookies here. By continuing to browse this site, you are agreeing to our use of cookies.

MaxiDrill Min-till Drills

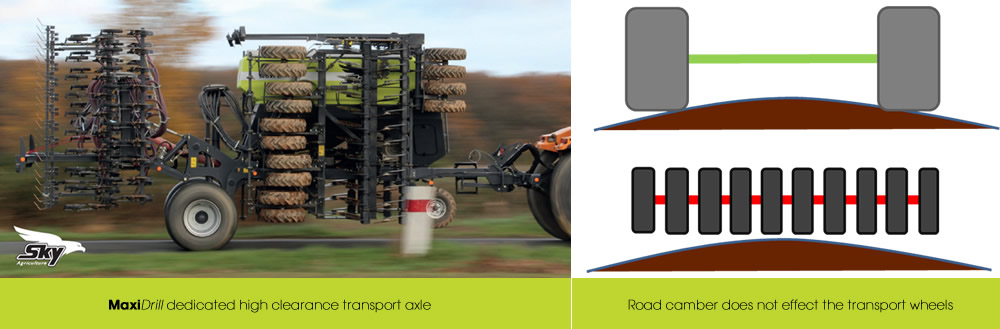

The MaxiDrill is designed as a high speed trailed minimum tillage drill but works equally well on ploughed and prepared seedbeds and can be used as a direct drill in certain conditions. The key feature of the MaxiDrill is the space within its construction which allows it to cope extremely well in wet, sticky and trashy conditions. This enables drilling in heavy residue seedbeds and late into the season when most other minimum tillage drills have been put away in the shed. Its road legal high speed axle allows fast transport between fields and farms and means a comfortable ride for the operator whilst enabling the press roller just to be used for consolidation whilst seeding and not for transport. 3m, 4m and 6m models are available with or without fertiliser.

A large easily accessible hopper with roll over hopper cover.

- Sky’s simple clever ideas that make a difference to everyday usage.

- Easy Emptying due to the emptying shutter and split folding design of the machine

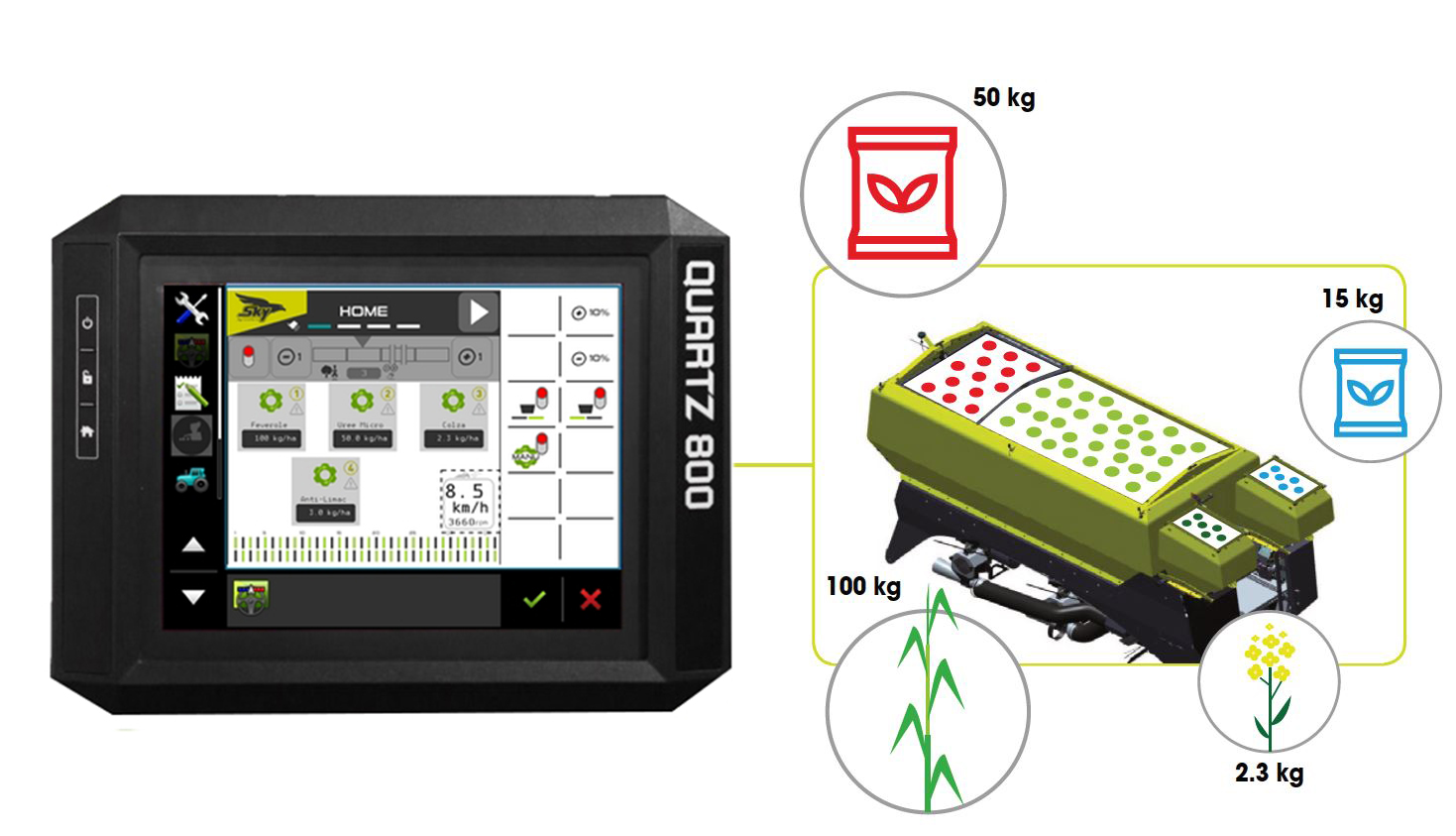

The all new electronics package maximizes the user benefits from Sky’s separate distribution systems and industry leading seed metering technology. At the heart of this is the Quartz 800 control box. All four metering units are controlled from the full colour touch-screen console making Sky drills exceptionally user friendly. Furthermore, variable rate seeding on all four hoppers is now a possibility and in addition all 20 Series drills are ISObus ready.

The Pro Hopper is an additional 120 litre small seed hopper that can be mounted on the MaxiDrill. 1 or 2 Pro Hoppers can be fitted to the MaxiDrill to apply slug pellets, micro-fertilisers or small seeds at the same time that the drill is seeding. Effectively this allows the MaxiDrill to seed four products in one pass, with all four of the seed hoppers being controlled by the one Quartz 800 controller. The product metered by the first Pro Hopper is introduced into the seed distribution system while the second Pro Hopper has its product introduced in to the fertiliser distribution circuit.

- Steps and open design provide easy access to the metering mechanism to adjust and calibrate the machine.

- Single roller metering mechanism with adjustable opening and gearing means no spare seed rollers need to be carried with the drill. The seed rate can be adjusted from 0.5 to 450kg/ha.

- Electric driven metering system allows easy calibration, accurate setting and variable rate.

- Push button calibration makes the drill very simple to set up accurately.

- Forward speed reading provided by the GPS sensor.

- The Quartz 800 allows the operator full control of the seed (and fertiliser) metering from the cab and can be integrated with mapping systems to vary seed and fertiliser rates.

- Electronic pre-load facility for starting drilling ensures the seed is metered at full rate from the start of the drilling run.

- Seed Head – Seed is distributed by the ADS head which accurately delivers the correct amount of seed down each outlet.

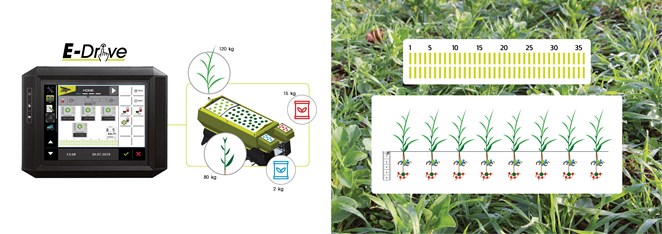

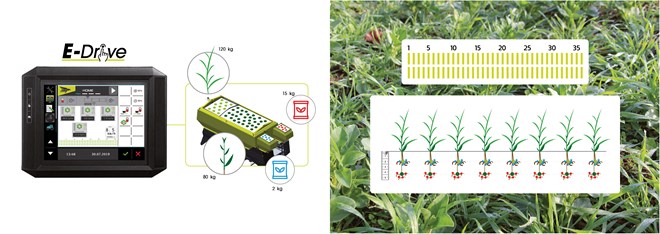

- The E-Drive Premium model allows individual rows to be electronically selected and then electronically engaged and disengaged. Every other or any number of rows can be shut off allowing wider row spacing with one seed or rows to be planted with alternating seed types. Tramlines are selected in the same way and as a result spacing of row shut off's are easy to alter from field to field if necessary.

- Accuracy – The Sky metering mechanism and ADS head provide unrivalled accuracy when drilling small or large seeds. This was tested by the German agricultural research institute and given an excellent rating for both small and large seeds.

This is where Sky drills benefit from their manufacturing partnership with Sulky, experts in fertiliser metering and application. All MaxiDrills come with a split grain and fertiliser hopper as standard. This consists of dual metering systems feeding two distribution heads which allows the fertiliser to be applied separately to the seed but in the same pass. A single control box with independent control of the two metering systems allows different rates of seed and fertiliser to be applied. These rates can be varied by the operator on the move or controlled by a GPS mapping system. Alternatively Slug pellets and seed or two seed types can be drilled at the same time. The primary seed is drilled using the disc coulter and the secondary product is applied by dedicated coulters in front of the press wheels.

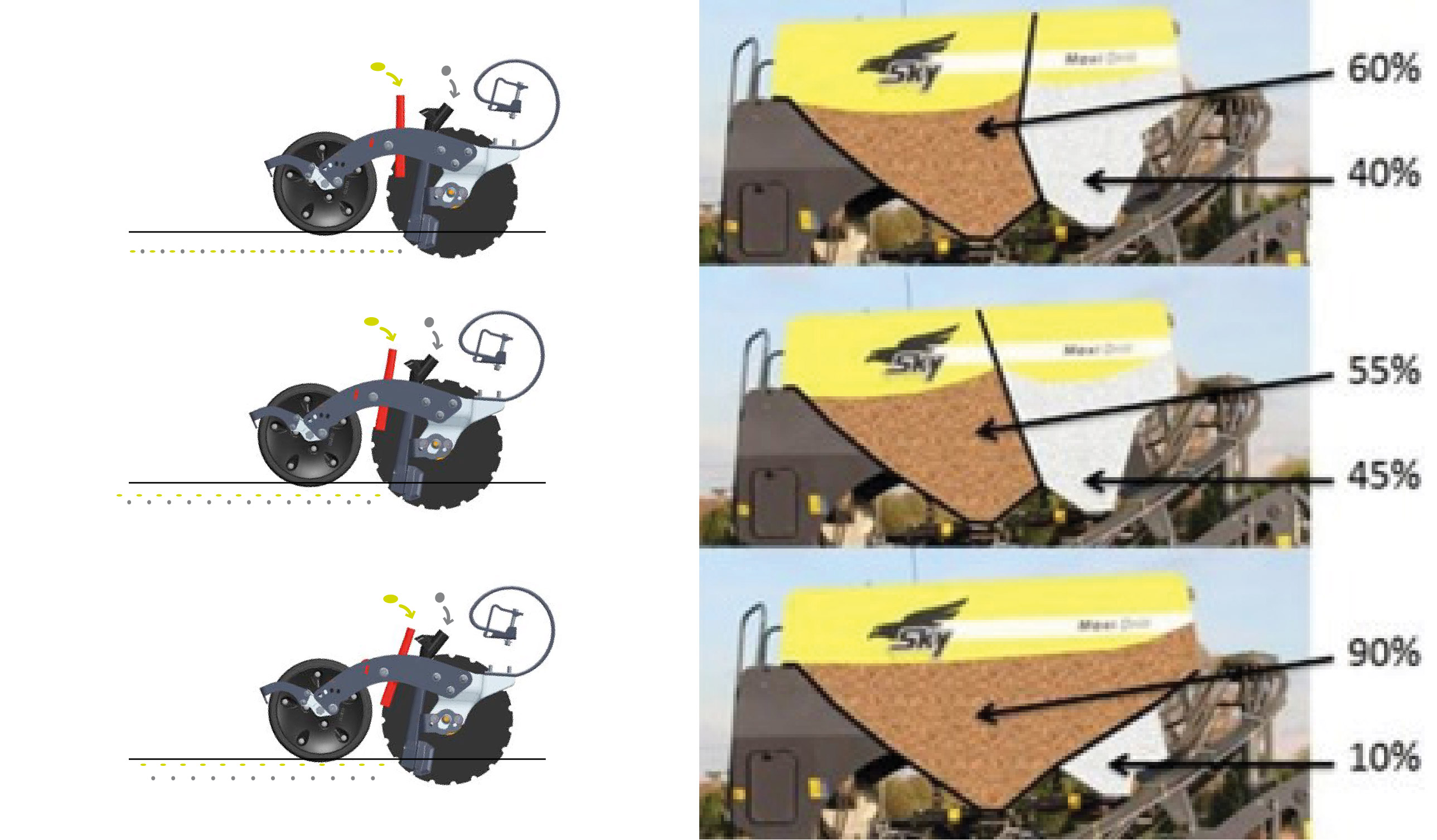

- Variable capacity split hopper – The hopper division can be moved to allow a variable split between seed and fertiliser or 90% of the hopper capacity to be used for seed only.

- The fertiliser coulters are positioned one between each pair of seed coulters. Low pressure fertiliser distribution provides for precise positioning of the fertiliser between seed rows. High pressure fertiliser distribution spreads the fertiliser across the full drilling width.

- Paint – All Sky drills undergo a fertiliser proof painting process to ensure their longevity no matter whether they are used for fertiliser or not.

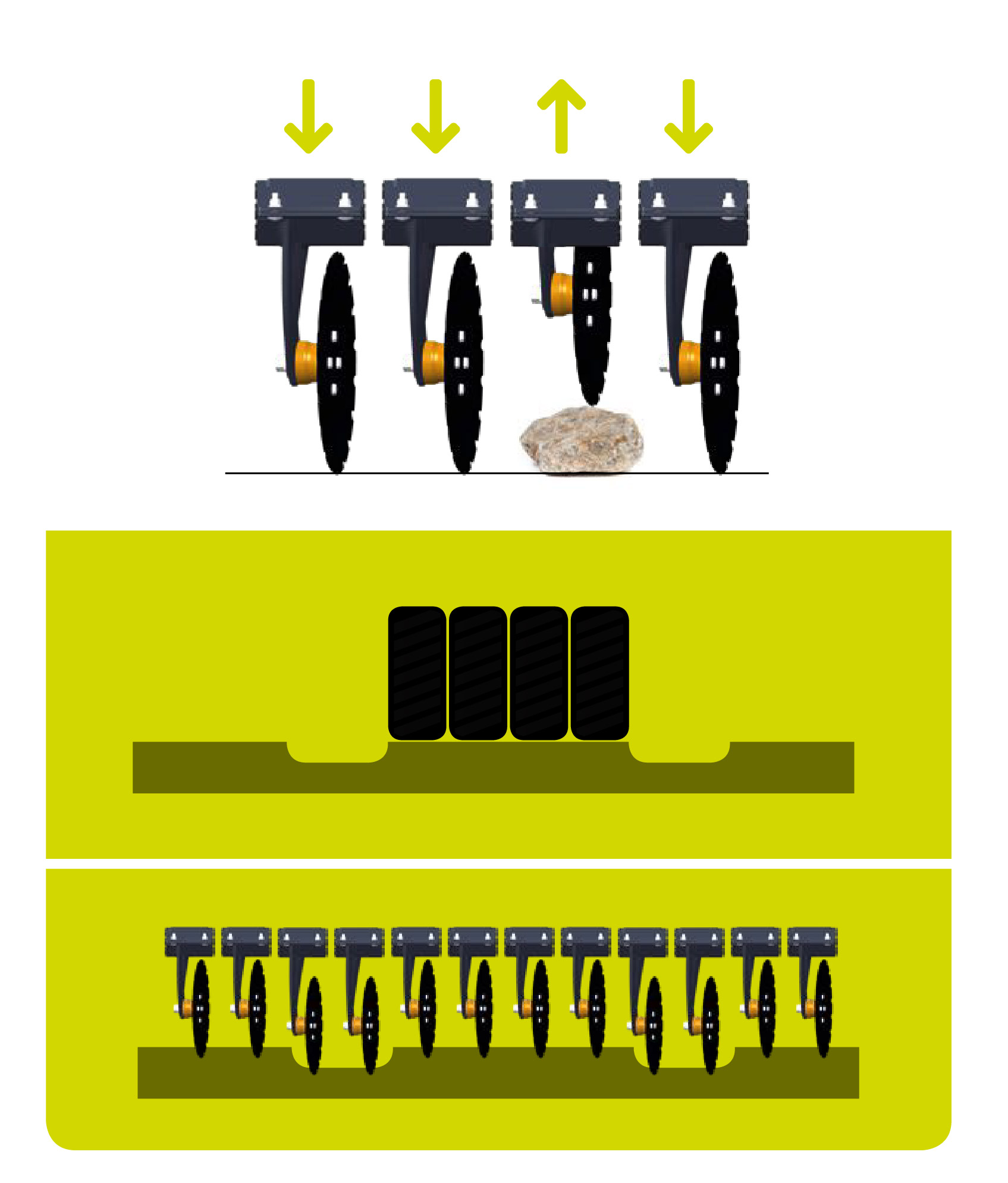

Cultivate and produce a fine tilth in front of the press. Individually mounted on rubber mounts for protection against stones. A slightly concave disc with small scallops moves and cultivates all the ground across the working width. Works at high rpm due to its size which creates a finer tilth for the seed to be placed in. Hydraulically adjustable from the tractor seat to suit conditions.

|

|

|

|

A full width row of staggered press wheels consolidate the seedbed behind the cultivation discs and ensure that the coulters are presented with a uniform and even soil surface to work in. The stagger of the press wheels reduces the HP consumption of the drill, especially when working in light soils as it minimises pushing soil along in a bow wave in-front of the wheels. Easy access to the tyres in order to change punctures should they arise.

The press wheels are only used in work in the field as the drill has a dedicated axle for road transport. This means that the tyre pressures can be set for field work and not for transport. This ensures flexing to allow them to keep clean in sticky conditions and reduces possible puncture damage due to high inflation. It also reduces the chance of surface compaction in wet soils that are prone to this.

Levels the soil and leaves some loose particles on the surface to prevent capping.

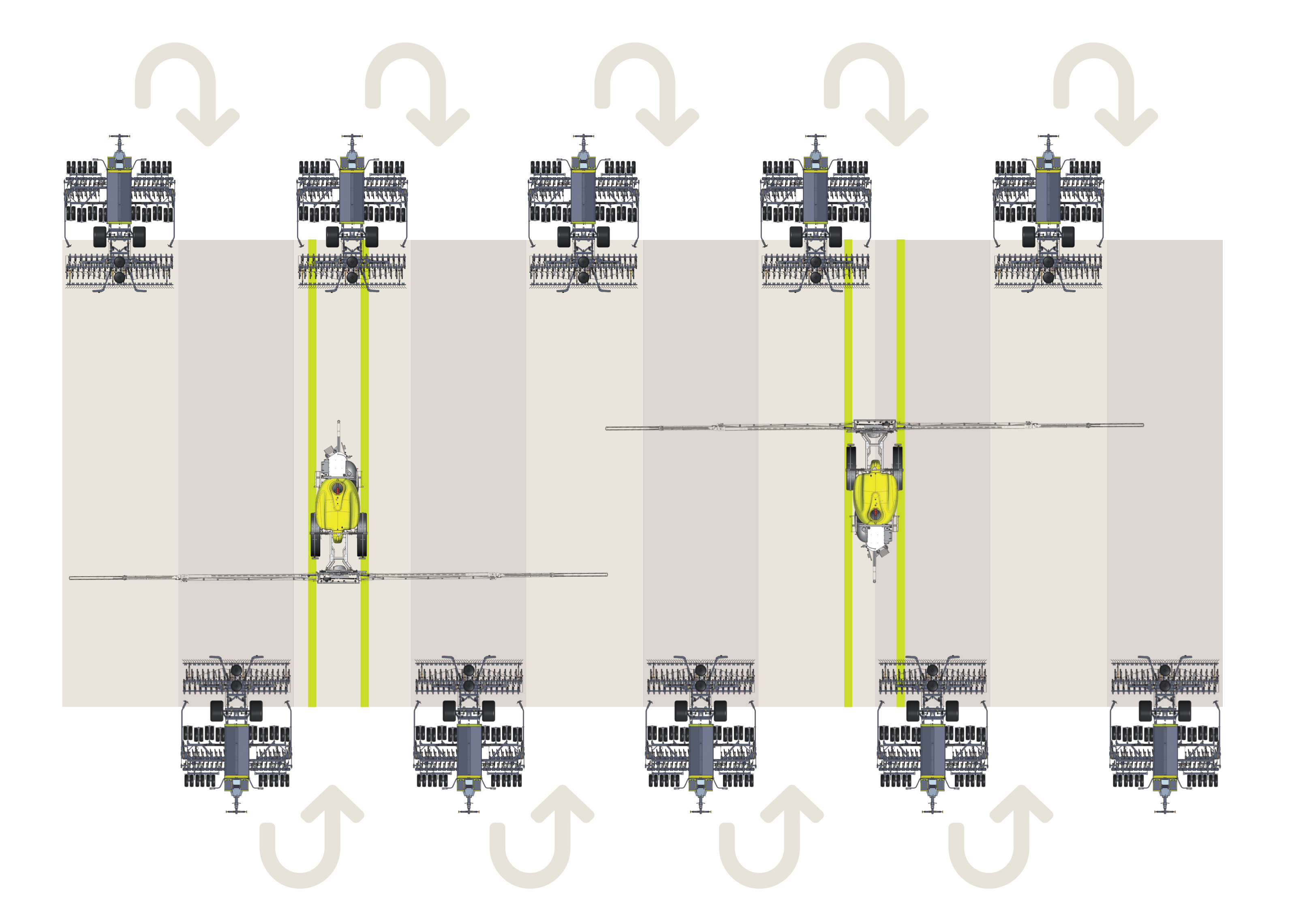

The top-spec option for the new drills is ‘E Drive Premium’. As well as offering left and right section control, E Drive premium provides electronic shut off for each individual outlet, with the result that the drill can be set to seed with any number of row configurations from the touch of a button.

This ability to shut off individual rows means that whatever the width of the sprayer or spreader it no longer needs to be a multiple of the drill width – simply enter the sprayer/spreader width into the control box and the tramlines will be calculated and set automatically. From now on the customer can change sprayer/spreader width without having to renew the drill - an extremely valuable function for contractors providing drilling services for customers with a range of different tramline regimes.

MaxiDrills can now be specified with blockage sensing for both the seed and fertiliser distribution systems to provide an early warning in case of any issues.

Easy to hitch, allows tight turns in transport and in the field.

The MaxiDrill is designed with a dedicated transport axle. This allows it to be fitted with hydraulic or air brakes and means the drill is safe and legal for high speed road transport. When using the MaxiDrill on a farm spread over many miles this can be a great benefit to productivity as well as providing peace of mind for the operator and owner. As the drill is fitted with the road axle and two large tyres there is no problem with the camber on the road affecting steering or overloading the central wheels of a full width press roller used for transport. High clearance for transport due to the transport axle and two section folding.

|

MaxiDrill 3020 Fertisem

|

MaxiDrill W 4020 Fertisem

|

MaxiDrill W 6020 Fertisem

|

|

|

Working Width (m)

|

3 | 4 | 6 |

|

Transport Width (m)

|

3 | 3 | 3 |

|

Weight (kg) (without options)

|

4,200 | 6,800 | 8,350 |

|

Hopper Capacity and volume allocation (l)

|

3,000 1,760 +1,240 or 1,440 + 1,560 |

3,000 or 1,760 + 1,240 or 1,440 + 1,560 |

4,100 or 2,450 + 1,650 or 1,800 + 2,300 |

|

Pro I Hopper

|

120 |

120 |

120 |

|

Pro II Hopper

|

120 | 120 | 120 |

|

Loading Height (m)

|

2.48 | 2.60 | 2.90 |

|

Number of Coulters

|

20 | 28 | 40 |

|

Number of Fertiliser Outlets

|

20 | 28 | 40 |

|

Coulter Pressure (kg)

|

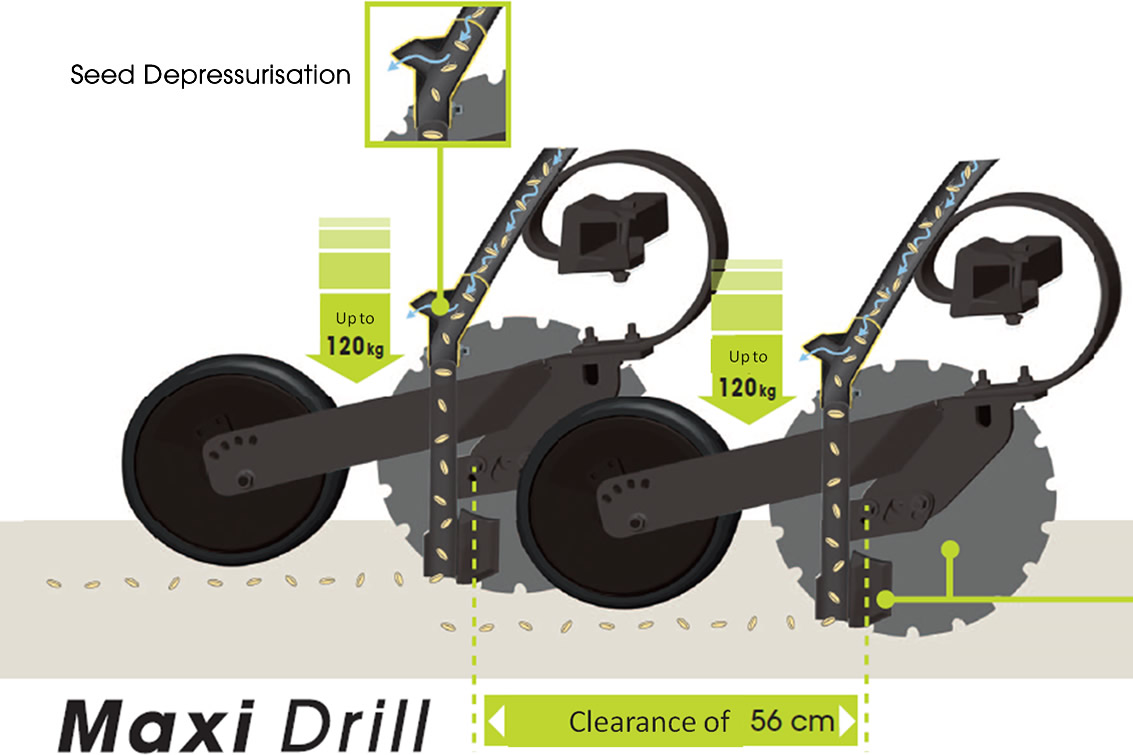

120 | 120 | 120 |

|

Row Spacing (cm)

|

15 | 14.3 | 15 |

|

Typical Working Speed

|

8 - 20 | 8 - 20 | 8 - 20 |

|

Power Required (hp)

|

105 - 150 | 140 - 200 | 210 - 300 |

|

Oil Flow Required for Fan (l/min)

|

40 | 40 | 40 |

|

Control Box (standard)

|

Quartz 800 | Quartz 800 | Quartz 800 |

Front Central Press - Recommended on well worked seedbeds, essential on ploughed ground.

Front Lateral Press - Recommended on ploughed ground for even consolidation across the working width.

Press Wheel Scrapers.

Pair of Eradicator Tines.

Work Lights - Long life LED lights.

Pre emergence Markers.

Independent Hydraulic tank with pump – For PTO drive of Fan.

Additional no ridge Harrow behind the staggered roller – For use on very light soils.

Additional 1+1 tramline closing valves.

Two rows of identical leaf spring mounted coulters provide up to 120kg per coulter for consistent penetration and seeding depth even in tough conditions. This enables the drill to work as a direct drill in certain conditions as well as a mintill drill as it was designed.

Two rows of identical leaf spring mounted coulters provide up to 120kg per coulter for consistent penetration and seeding depth even in tough conditions. This enables the drill to work as a direct drill in certain conditions as well as a mintill drill as it was designed.